Pre-Engineered Metal Buildings

Pre-Engineered Metal Building Contractors

Pre-engineered metal buildings are known for their speed of construction, cost-efficiency, and design flexibility. These are just a few benefits that make them the ideal choice for business owners and operational managers looking to construct a new facility or warehouse they can rely on for years to come.

A.C.E. Building Service takes pride in being an industry-leading pre-engineered metal building (PEMB) contractor. Through a long-standing partnership with Butler Manufacturing, we deliver state-of-the-art pre-engineered metal building solutions to a diverse range of industries.

Keep reading to learn more about pre-engineered metal buildings and why choosing A.C.E. Building Service as your PEMB contractor may be the best choice for your business.

What Is a Pre-Engineered Metal Building?

Pre-engineered metal buildings are precisely what their name suggests: structures that are engineered and fabricated in advance to fit the exact specifications of a project. These steel building systems have revolutionized the way we approach the design and assembly of commercial and industrial buildings.

Unlike traditional construction methods that often require extensive on-site welding and field modifications, pre-engineered buildings arrive at the construction site with most of the components ready for assembly with bolted connections and laser precise factory drilled or punched holes, which helps to significantly speed up the construction process.

Pre-engineered metal buildings are not cookie-cutter structures but rather customized to meet the specific needs and requirements of each project. Whether you're looking for a straightforward single-building solution, expand your existing building footprint, or need a complex of multiple buildings, pre-engineered metal buildings offer a fast, affordable, architecturally appealing, and environmentally friendly solution that can be tailored to any unique vision.

Industries Best Suited for Pre-Engineered Metal Buildings

Due to their design flexibility and energy efficiency, pre-engineered steel buildings are ideal for a variety of different industries and building types, including:

- Storage warehouses

- Manufacturing facilities

- Industrial facilities

- Sports and Recreation complexes

- Municipal

- Aviation

- Commercial Retail

- Automotive shops/dealerships

- Office buildings

- Schools, Colleges, Universities

- Medical clinics and laboratories

- Climate Controlled Storage

Advantages of Pre-Engineered Metal Building Construction

When building owners and operation managers look for a reliable, durable building that will last, they often turn to pre-engineered metal buildings. Below are a few key advantages of pre-engineered metal building construction.

- Rapid construction timelines — Butler components are fabricated in a controlled manufacturing environment with laser-precise equipment, promoting quick and easy construction when the materials arrive at the job site.

- Cost-effective solutions — A Butler pre-engineered structure is designed with cutting-edge technology and engineering principles to optimize the steel required for your building. A pre-engineered structure will require far less steel than conventional steel structures, saving you money.

What’s more, the precision-engineered structural steel is designed with advanced computer modeling for faster assembly when the building arrives at the job site location, reducing construction time and cost. - Durability and strength — Suited for nearly any climate and backed by the tried and true MR-24 roof system, your Butler building will stand the test of time.

- Customizable options — The sky's the limit for a pre-engineered structure. From million-plus square foot buildings, to aviation hangers, to heavy industrial uses, or a simple storage structure the adaptations for use are endless.

- Sustainable materials — All Butler buildings contain up to 74% recycled steel and can be disassembled and recycled at the end of their life.

- Energy efficiency — Butler buildings can be designed with a wide array of roof and wall systems that are able to offer high R-value assembly ratings and promote energy efficiency.

- Low maintenance — A Butler pre-engineered structure and the Butler MR-24 roof are designed for long-lasting performance that easily exceeds the lifespan of most conventional roof systems, saving you money over the life of the building.

How Long Does It Take to Construct a PEMB?

Much like constructing a traditional building, several factors can influence how long it takes to build a PEMB, including size and complexity, site preparation, permits, weather conditions, and more.

Those elements are a constant with any type of structure, so what makes a Butler building faster to construct? For starters, all of Butler’s secondary framing components are factory punched, with holes precisely located for fast and accurate installation at the job site.

The mainframes are prime painted gray, and all the exposed secondary framings are acrylic-coated galvanized steel, ready for finish paint if that is the desired look. However, when complemented with white-faced insulation, the appearance is so clean and highly reflective that most clients choose to leave everything unpainted.

In most cases, the foundation for the building can be constructed while the building is being fabricated in one of Butler’s six North American manufacturing facilities. When the building arrives at the job site, it is ready to be erected almost immediately.

Looking to build a new manufacturing plant or facility? Learn about the 10 crucial steps to planning your construction project in this blog post.

How Much Does a PEMB Cost?

Buildings are unique entities — the overall cost of your pre-engineered metal building will depend on its size and specific project requirements. Different PEMB sizes come with varying material, labor, and engineering expenses. Additionally, fluctuating steel prices and changing engineering requirements make it difficult to provide an estimated cost. Because of this, there is not a sliding scale or “one size fits all” cost that can be applied to a PEMB.

For the most accurate estimate, consult with a reliable PEMB contractor. They'll assess your project specifics, highlight cost factors, and provide a tailored estimate, ensuring your budget aligns with your PEMB goals. In many cases, a PEMB structure will be more cost-effective than a conventional steel or wood-framed design.

We understand choosing the right metal building size and design is a decision that can significantly impact the success of your business. It can be overwhelming to think about the time and financial investment, so we created our metal building design gallery. The virtual gallery features six unique buildings, all of which can be built as is or customized to fit your needs. Start designing your metal building now!

What Is the Average Lifespan of a Pre-Engineered Metal Building?

Metal buildings face fewer issues with deterioration and rot than wood structures, setting them up for long-term success when properly built and maintained. Pre-engineered metal buildings began to be widely used during the Second World War and gained immense popularity in the 1960s, many of which are still in service today. With technological advancement in roofing systems, paint finishes, and steel quality, you can expect decades of dependable use and lifespan.

All structures will need maintenance to ensure a long lifespan. How long your metal building lasts can be influenced by maintenance and upkeep. Regular maintenance for a metal building system typically includes roof inspections, keeping debris clear from gutters and downspouts, maintenance of proper drainage away from the building, protection of building columns from movable objects such as vehicles and forklifts, and a proper interior environment that protects steel components from corrosion.

Following maintenance guidelines and working with your PEMB contractor on future maintenance and upkeep will help ensure the longevity and performance of your metal building.

Choosing a Pre-Engineered Metal Building Manufacturer

At A.C.E Building Service, we demand durability and integrity in all the materials and products we use, which is why we chose Butler Manufacturing as our pre-engineered metal building manufacturer. Over the last 50 years as an official partner with Butler Manufacturing, we have consistently witnessed the unparalleled strength of Butler's metal building systems.

Their cutting-edge designs coupled with high-quality materials ensure longevity and resilience against the elements. Beyond durability, Butler's innovative pre-engineered metal building solutions provide flexibility and customization, allowing us to tailor structures to the unique needs of our clients. The efficiency of Butler's building systems translates into streamlined construction processes, ultimately saving our clients time and costs.

Learn more about our partnership with Butler Manufacturing!

What Should You Look for In a PEMB Contractor?

Experience is the most important thing to look for when choosing a PEMB contractor. Constructing a pre-engineered metal building is a unique process, and the more experience a contractor has the more likely they will make quick decisions, work efficiently, and predict and avoid potential problems. They will also have the experience needed to suggest the best PEMB design for your business needs now and how to structure your building in a way that can easily adapt to future growth.

A PEMB contractor should also have a close relationship with their pre-engineered metal building manufacturer and have the resources and support they need to ensure every pre-engineered building they construct is built in the most efficient way possible.

A.C.E. Pre-Engineered Metal Building Construction Services

A.C.E. Building Service is a pre-engineered metal building contractor with a track record of successful projects. Backed by the support of Butler Manufacturing, our services are tailored to meet your project needs.

Our pre-engineered metal building services include:

- Budgeting and expert Butler design consultation

- Preconstruction services

- Complete construction management and design-build services, from permitting to project completion

- Maintenance and repairs

Sixty years of construction experience and fifty years as a Butler Builder means we have the knowledge to turn your pre-engineered metal building vision into reality. Contact us today!

Check out some of our pre-engineered metal building projects by clicking below!

Additional Pre-Engineered Metal Building Services

In addition to conventional steel building structures, A.C.E. Building Service provides design and installation services for Butler's MR-24® Roof System and Express Mezz™ System. These systems can be seamlessly incorporated into any new construction schedule or offered independently, such as the redesign or upgrade of an existing facility’s interior and exterior space.

The MR-24® Roof System

Features and Benefits

- Acts like a monolithic steel surface covering your entire building and providing superior protection

- Specifically designed with movable clips to accommodate roof movement under changing temperatures

- The only PEMB roof available with the 360-degree Pittsburgh double-lock seam, with the final 180 degrees field rolled, for superior performance and protection

- Factory-punched panels and structural members assure proper alignment and accurate installation

- Accommodates additional insulation thicknesses to enhance energy efficiency

- A material-efficient option with compelling sustainability attributes

- Available in several cool colors for added energy savings

- Can save up to 90% on roof maintenance costs when compared to conventional roof systems

Check out why Butler’s MR-24 Metal Roof System is superior to all other metal roof systems in this blog post!

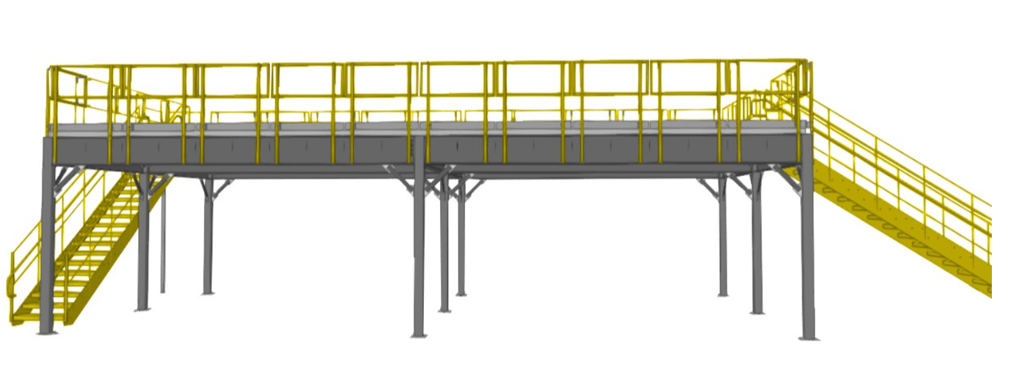

Butler Express Mezz System

Features and Benefits

- The freestanding design allows you to order for an existing or a new building

- Gives you the ability to maximize facility space at a minimal cost

- Built-in flexibility with two standard heights of 9’ or 10’ for clearance and six floor surface options which include pallet jack ratings up to 2800 pounds, one 4” cast-in-place concrete flooring option and a 3/4" board option

- Easy system installation with no welding required

Learn about how you can maximize your warehouse space with a Mezz System in this blog post!

Pre-Engineered Metal Buildings: Recycled Steel and Sustainability

As companies prioritize environmental responsibility, many are actively adopting more sustainable practices. Recognizing steel as the most recycled material globally, Butler incorporates recycled steel into its integrated steelmaking processes. This not only minimizes industrial waste but also significantly reduces the carbon footprint associated with steel production, aligning with the broader industry trend toward greener construction practices.

FACT: All Butler Pre-Engineered Metal Buildings contain up to 74% recycled steel and are designed to be easily disassembled and reused or recycled.

See a Pre-Engineered Metal Building Project From the Ground Up

See A.C.E. in action by watching the videos below, where we construct a pre-engineered metal building from the ground up!

The above videos show the construction of Phase I (Pre-Engineered Metal Building) and Phase II (Conventional Steel) of Dramm Corporation's new corporate headquarters. Check out more project details and images here!

Why Choose A.C.E.?

At A.C.E. Building Service, we are proud to be the trusted pre-engineered metal building contractor in Northeast Wisconsin and the Lakeshore. Through “The Butler Difference,” we guarantee the unmatched durability and flexibility of Butler Building Systems, engineered and installed by an industry-leading, experienced team.

We offer award-winning commercial and industrial metal building construction services with a reputation for being trustworthy, fair, and honest. We are happy to help assess your facility needs and will work with you to fully understand the best choice for your business.

Want to learn more about our metal building construction services? Call us today or complete the project consultation form. We look forward to hearing from you!

Trust A.C.E. Building Service and Butler Manufacturing’s metal building systems for your next project.

Additional Resources

Jeremy KassProduction and Engineering Manager, Tramontina USA, Manitowoc, Wisconsin

“We were most pleased with the professionalism displayed by the project managers and foreman. Tramontina changed the scope of the project before and during the project numerous times, and A.C.E. handled it very well and with little financial impact.”

What's Being Built In Northeast Wisconsin?

Subscribe for the Latest Construction News

About Us

A.C.E. Building Service offers design/build commercial and industrial construction services throughout Northeast Wisconsin and is the exclusive Butler Builder for the lakeshore from Sheboygan to Door County.