Together with increased industry customer demands and the abilities of specialized contractors, such as A.C.E. Building Service, the future of commercial and industrial building construction is here.

Welcome to the future of construction. Have you dined with us before? Our specials include:

- Faster construction project timelines

- Employee-focused workspaces

- Flexible building designs

- Sustainable building materials

Bon appetit!

Faster Construction Project Timelines

Time is money. The faster a building is completed, the sooner it can start generating income for its owner. In today's fast-paced construction industry, the pressure to deliver projects quickly is more intense than ever. With advancements in technology, the timelines for both the preconstruction phase, including budgeting and design, and the overall construction process are continually shrinking. What once took months to accomplish is now expected to be completed in weeks.

Working with Bulter Manufacturing and utilizing their pre-engineered metal building systems has allowed us to implement the design-build project delivery method, where contractors, designers, subcontractors, and owners work together from the beginning. This integrated approach helps us reduce overall project costs and deliver projects faster without compromising quality.

Explore the three key benefits of design-build construction in this blog post.

Butler’s pre-engineered metal buildings can be erected in a fraction of the time it takes to construct a conventional masonry and steel structure, which helps accelerate project timelines. Here's how:

- A pre-engineered building can be delivered in as little as six weeks.

- Butler’s pre-punched structural materials enable fast, efficient erection at the job site.

- There are no redundant building elements, eliminating unnecessary steps and saving valuable time and resources.

For example, unlike other traditional building methods that require multiple layers of installation, such as steel decking, insulation, and finished roof surfaces, pre-engineered metal structures streamline the process. With the metal roof panel serving dual purposes, our clients enjoy significant time and cost savings, putting income in their pockets sooner.

By harnessing the speed and efficiency of Butler's pre-engineered metal buildings, A.C.E. Building Service ensures your project is not only completed faster but also with uncompromising quality and precision. Learn more here.

Employee-Focused Workspaces and Flexible Building Designs

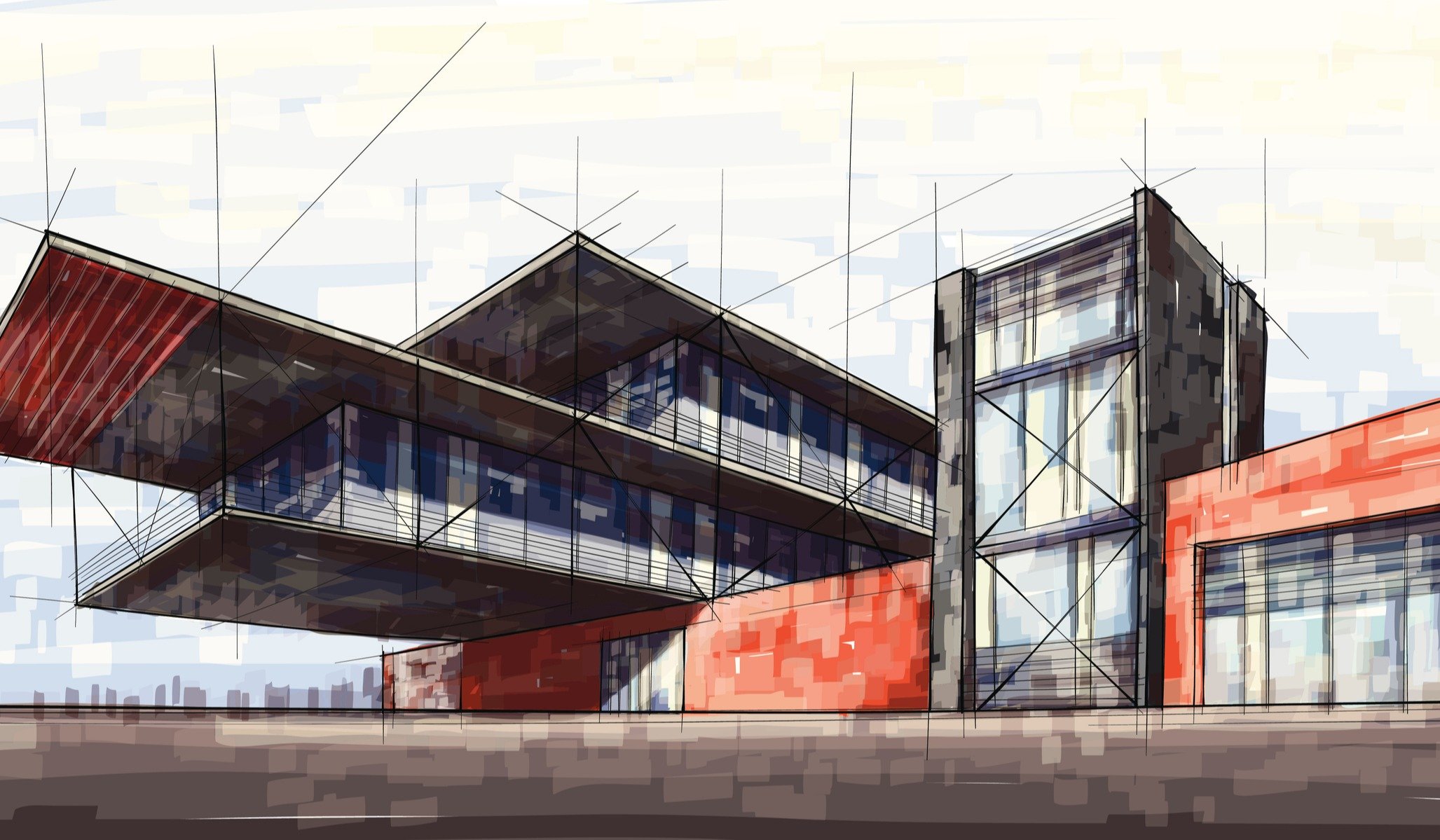

In today's competitive business landscape, employers are understanding just how important a work environment is in fostering employee satisfaction, well-being, and productivity. In the past, buildings were designed and constructed primarily with business operations in mind. Today and in the future, employee productivity and satisfaction will be a huge driver in building design.

At ACE Building Service, we work with our clients to design our Butler pre-engineered metal buildings with workspaces that prioritize health, happiness, and collaboration. We prioritize the following features to design the optimal building environment that helps attract and retain top talent:

- Ample Natural Lighting: Open designs with abundant natural light not only enhance mood and productivity but also contribute to overall well-being.

- Advanced Air Filtration Systems: Our buildings can easily be equipped with state-of-the-art air filtration and HVAC systems to ensure optimal

indoor air quality, promoting a healthy and comfortable workspace. - Thoughtfully Planned Layouts: Together with our clients, we design open layouts that drive productivity, encourage engagement and collaboration, and foster a sense of teamwork and innovation among employees.

From energy-efficient lighting to furniture and desk placement, we incorporate a range of amenities tailored to the needs of modern workplaces. Whether it's fitness centers, informal cafes, locker rooms, or conference rooms, our Butler pre-engineered buildings can be designed to enhance creativity, productivity, and overall employee satisfaction.

See how you can enhance your facility design in this blog post.

Sustainable Building Materials

The future of construction is sustainability. The supply of natural resources is not limitless. This is something we need to consider yesterday, today, in the future, and for decades to come. The use of sustainable building materials is more important than ever.

Steel is a renewable material. It’s the most recycled material on earth, and recycled steel is an essential ingredient used in Butler’s integrated steelmaking processes. The electric arc furnace process is more environmentally friendly than basic oxygen furnaces—enabling the use of 75%–100% recycled steel.

Steel is a renewable material. It’s the most recycled material on earth, and recycled steel is an essential ingredient used in Butler’s integrated steelmaking processes. The electric arc furnace process is more environmentally friendly than basic oxygen furnaces—enabling the use of 75%–100% recycled steel.

All Butler pre-engineered buildings contain up to 74% recycled steel and are all designed to be easily disassembled, repurposed, or recycled.

The demand for products and systems that can reduce energy consumption is higher today than ever before. Butler also offers a range of energy-efficient roof and wall systems that can achieve a thermal efficiency rating of R-40 or more if required.

By partnering with Bulter Manufacturing, we are working towards a more sustainable future in construction. Now that’s a smart and responsible future to be a part of and live in!

The Future of Construction Is Pre-Engineered

You’ve heard why steel materials are important for sustainability and how Butler’s pre-engineered building systems, paired with our design-build delivery method, can speed up construction timelines, but why else should you consider pre-engineered steel buildings?

- A pre-engineered steel structure is non-combustible, which allows for more lenient building code requirements and lower insurance rates.

- Pre-engineered structures are adaptable and can be designed with future expansion in mind and added on to with ease.

- Pre-engineered buildings can be designed to accommodate almost any end-use building. From warehouses to churches, aircraft hangers to office buildings, self-storage to heavy and unique structures, we can design a Butler building to fit any need and design.

Explore Our Metal Building Design Gallery

Sold on a pre-engineered metal building but still need more help deciding on the best size and model? We have you covered with our virtual metal building design gallery. It features six of the most popular Butler pre-engineered metal building designs and sizes, all of which can be constructed as is or fully customized to fit your vision and business needs.

How Does Butler Manufacturing Stay Ahead of Commercial Construction Trends?

Butler has been recognized as the industry leader in pre-engineered steel buildings for years now. They continuously improve supply chain management, engineering, energy code compliance, and technology, giving Butler Builders and its clients the tools to design cost-effective, energy-efficient, and easily-adaptable structures.

Butler Manufacturing even has its own research center and a proprietary real-time estimating system that can generate a firm price for most building solutions in minutes. Butler’s team members come from a wide background in the construction industry, including engineers, former builders, LEED-accredited professionals, real estate developers, and those with a background in heavy structures.

Learn why Butler Manufacturing is the industry-leading manufacturer of pre-engineered metal buildings.

Why Choose A.C.E. Building Service?

A.C.E. Building Service takes pride in being your trusted local Butler builder and primary source for pre-engineered metal buildings. Recognizing that the future of construction is already here, we leverage Butler's cutting-edge technology and metal building systems to remain at the forefront of industry trends. This enables us to provide expedited project timelines and flexible metal building designs, all while reducing our environmental impact and maintaining superior quality.

We offer commercial and industrial construction services in Manitowoc, Sheboygan and Wisconsin's Lakeshore Area. Click the image below to start designing your metal building, or contact us today!