Construction Resources

Construction Resources

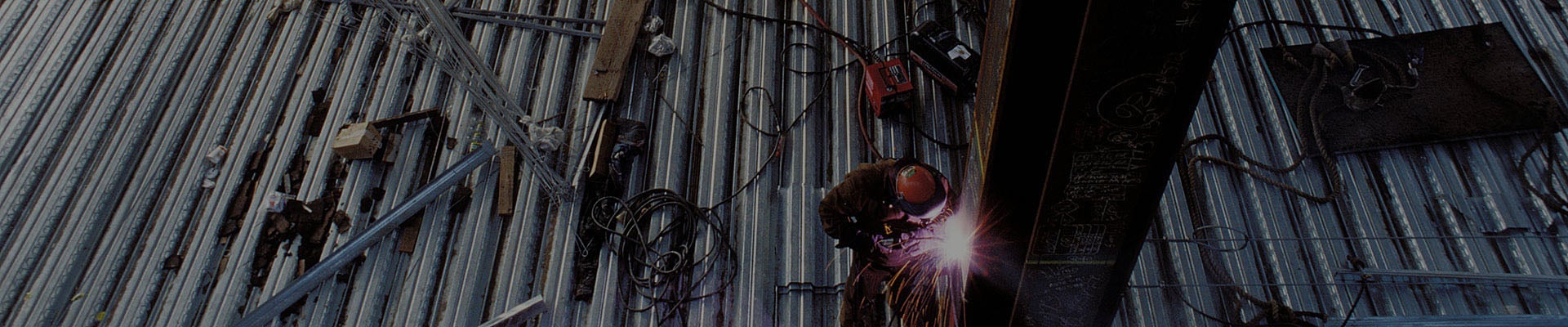

Building Northeast Wisconsin Since 1963

New construction technology and innovations are transforming the way projects are planned, built, and delivered, making the process faster and safer than ever. Digital tools are becoming increasingly advanced, keeping teams aligned in real-time. Robotics and smarter equipment are reducing strain and preventing on-site injuries, and the list goes on. It seems that every day, we are introduced to a new advancement that will help contractors do more with less and improve project outcomes. Below, we’ll explore some of the most impactful construction technology trends and other innovations that are driving change across the industry.

Read More

Choosing the right general contractor is critical when planning to expand or construct a new manufacturing facility. The success of your project depends on this choice, as a reliable contractor ensures a successful project outcome that meets quality, budget, and timeline expectations. At A.C.E. Building Service, we’ve worked with manufacturing businesses across Manitowoc, Sheboygan, and Wisconsin’s Lakeshore Area for decades. In this blog post, we draw on our extensive experience in industrial and manufacturing construction to provide you with the insights and knowledge needed to select the best general contractor for your specific manufacturing construction needs.

Read More

What's Being Built In Northeast Wisconsin?

Subscribe to see all the latest news from A.C.E. Building Service. We promise we will not flood your email inbox, and we never, ever share our contact list. We promise.

Subscribe for the Latest Construction News

About Us

A.C.E. Building Service offers design/build commercial and industrial construction services throughout Northeast Wisconsin and is the exclusive Butler Builder for the lakeshore from Sheboygan to Door County.