A.C.E. Projects

Building Northeast Wisconsin Since 1963

When students returned to classes at the St. John/St. James Lutheran School in Reedsville, Wisconsin in January 2018, excitement was in the air. Students, staff and parents lauded the new facilities, made possible by the demolition of an outdated building originally constructed in 1903 and the construction of a 16,500-square-foot addition to the church. The project was funded by a $2 million commitment from the church community that owns and operates the school. St. John–St. James provides quality education to students in kindergarten through 8th grade. Now students can enjoy the new amenities, including a new gymnasium with main and practice courts for basketball and volleyball, a commons area, a kitchen, private offices, locker rooms, and renovated bathroom facilities. The addition also created something the church school community had long wanted: a physical link between the church and school that eliminates the need to exit a building to move between either space. The expansion also creates the necessary space to expand its early childhood program. The school, located at 223 Manitowoc Street in Reedsville, drew a lot of attention in this small, tight-knit community. There was an audience for the demolition work that removed the original structure, making room for new construction. The school's prominence in the community meant that construction also garnered much attention.

Read More

Founded in Brazil in 1911, Tramontina brought its business to the U.S. in 1986. The company has been manufacturing cookware at the Wisconsin facility since 2005. The plant is one of the facilities made available when the former Mirro Co. cookware plant shuttered its operations in 2003. “At a time when cookware manufacturers were moving operations abroad, Tramontina revived a cookware factory in Manitowoc, Wisconsin, reemploying local laborers and bringing its aluminum production to the U.S.,” notes Tramontina’s corporate website. “Reviving this plant allowed a skilled local workforce to keep their jobs and allowed the town of Manitowoc to retain its long-established identity of craftsmanship in aluminum cookware manufacturing.” Today, Tramontina manufactures more than 25 million pieces of cookware each year in the United States. In early 2017, Tramontina US Cookware invited the A.C.E. Team to make improvements and help expand the company’s Manitowoc manufacturing facility.

Read More

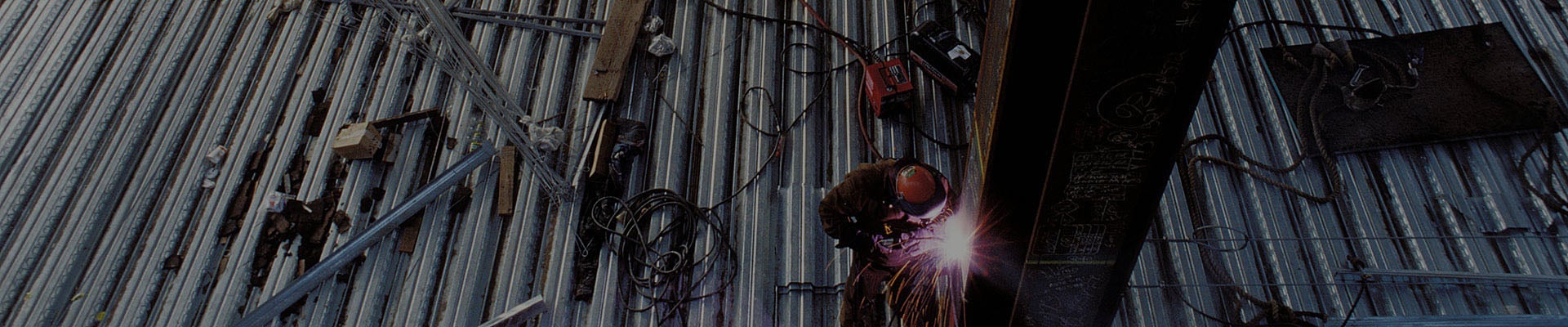

Our recent work for Skana Aluminum Company in Manitowoc, Wisconsin was tons of fun – literally. More than six tons, in fact. In 2017, A.C.E. Building Service was tasked with a casthouse expansion project for a new 21,500-square-foot facility. The expansion is part of a multi-phase project at Skana Aluminum initiated to replace its 1960s-era melting furnaces. The additional square footage made way for a new, state-of-the-art furnace and expanded raw material storage area. It is designed to accommodate a new furnace as one of the future stages in the overall project. Eventually, a total of three 50,000-pound capacity melt/hold/tilt furnaces and a new casting pit will replace the existing furnaces and casting pit. A Business and a Building Steeped in Tradition Skana is in a business — and a building — steeped in tradition. By the 1890s, aluminum was widely used in jewelry, everyday items, eyeglass frames, and optical instruments. Aluminum tableware was produced by the late 19th century and gradually supplanted copper and cast-iron tableware in the first decades of the 20th century. It wasn’t long before aluminum foil was invented, a mainstay of modern kitchens. Aluminum is soft and light, making an ideal material for a multitude of uses. It was soon discovered, however, that alloying it with other metals could increase its hardness while preserving the low density — a factor which led to even more uses for aluminum.

Read More

Stecker Machine Company, Inc. has announced an expansion project to accommodate its continued growth. Stecker and A.C.E. Building Service, the project’s design/build contractor, recently held a groundbreaking ceremony for the 6,270-square-foot addition, which will house the manufacturer’s sales and engineering staff. The new facility, a Butler® pre-engineered metal building, will be completed by spring.

Read More

A.C.E. Building Service has completed an expansion project for KNM, LLC in Manitowoc. The new 6,000-square-foot Butler® pre-engineered metal building adds to their existing 6,000-square-foot facility and creates greater capacity to support KNM’s customer needs. The expansion will also provide needed work space for current employees and allow room for additional growth.

Read More

What's Being Built In Northeast Wisconsin?

Subscribe to see all the latest news from A.C.E. Building Service. We promise we will not flood your email inbox, and we never, ever share our contact list. We promise.

Subscribe for the Latest Construction News

About Us

A.C.E. Building Service offers design/build commercial and industrial construction services throughout Northeast Wisconsin and is the exclusive Butler Builder for the lakeshore from Sheboygan to Door County.